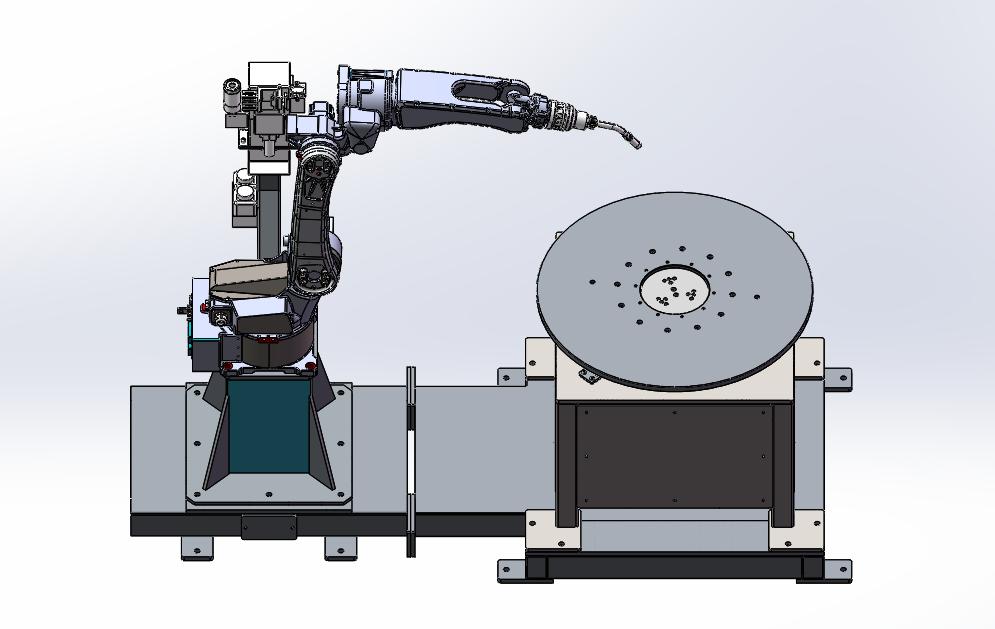

6 Axis stainless steel aluminium welding robotika workstation

Fitur

1. Desain kabel sing dibangun ing robot ngidini robot bisa mindhah tanpa gangguan lan tata letak workstation rapi lan rapi

2. Kabinet kontrol robot bisa ngontrol nganti 11 sumbu, ngindhari debugging PLC kompleks lan pendhudhukan ruang

3. Robot JHY lan positioner bisa disinkronake, lan robot bisa las bebarengan nalika positioner puteran, nggawe workstation iki utamané cocok kanggo welding bunder.

4. Ana macem-macem peralatan tambahan, kayata sensor laser, tirai lampu safety lan pager safety.

5. Sistem kontrol ngemot sawetara paket proses welding, sing ngidini mode welding beda digunakake kanggo workpieces beda.

Parameter teknis positioner

| Model | JHY4030D-080 |

| Dirating Tegangan Input | Fase tunggal 220V, 50/60HZ |

| Isolasi Motor Kab | F |

| Meja Kerja | Diameter 800mm (bisa disesuaikan) |

| Bobot | Udakara 400kg |

| Maks.Muatan | Axial Payload ≤300kg / ≤500kg / ≤1000kg (> 1000kg bisa disesuaikan) |

| Repeatability | ± 0,1 mm |

| Posisi Stop | Posisi Sembarang |

Komponen workstation robot

1. Robot pengelasan:

Tipe: MIG welding robot-BR-1510A,BR-1810A,BR-2010A

Robot las TIG: BR-1510B, BR-1920B

Robot las laser: BR-1410G, BR-1610G

2. Positioner

Model: JHY4030D-080

Tipe: 1-axis horizontal rotating positioner

3. Welding sumber daya

Tipe: 350A/500A sumber daya las

4. Welding gun

Tipe: bedhil air-cooled, gun banyu-cooled, gun push-pull

5. Stasiun resik obor:

Model: SC220A

Tipe: Pembersih obor las pneumatik otomatis

Peripheral workstation robot liyane

1.Robot obah alur

Model: JHY6050A-030

2. Sensor laser (opsional)

Fungsi: weld tracking, positioning.

3. Tirai lampu safety (opsional)

Jarak protèktif: 0.1-2m, 0.1-5m;dhuwur protèktif: 140-3180mm

4. Pagar keamanan (opsional)

5. Kabinet PLC (opsional)