China 6 Axis 1800mm Lengan tekan Baja Otomatis MIG Welding Lengan Robot

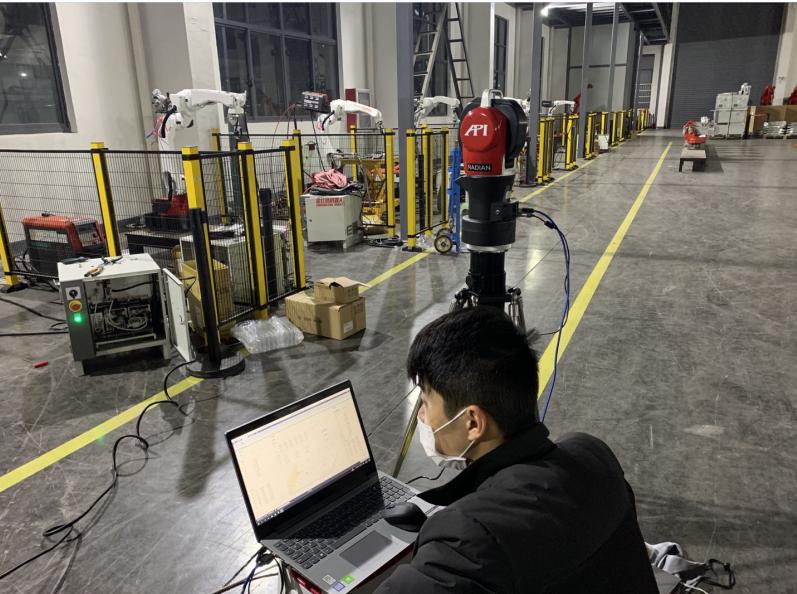

LASER KALIBRASI TEST REPOSITIONING Akurasi

JHY nggunakake metode kalibrasi laser kanggo nguji akurasi posisi robot sing bola-bali.Sawise pirang-pirang tes, akurasi posisi bola-bali robot kita luwih dhuwur tinimbang ± 0.08mm.

Gunakake TOP BRANDS kanggo AKSESORI Inti

Aksesoris inti robot kayata motor servo, reducer RV, reducer harmonik, drive servo lan liya-liyane kabeh nggunakake merek top China, sing wis diuji kanthi nggunakake jangka panjang kanggo mesthekake yen cocok kanggo robot kita.

MAINTENANCE SIMPLE

Maintenance punika prasaja, Miturut pandhuan pangopènan diwenehake dening kita pelanggan dhewe bisa gampang operate.

JAMINAN SALE

Saben pelanggan duwe klompok layanan sawise-sales dhewe.Yen sampeyan butuh bantuan sawise-sales, Pls takon kapan wae.Insinyur profesional kita bakal ngrampungake ing wektu paling cendhak.Intine kabeh iku gratis.

| Referensi paramèter welding kanggo baja ringan lan baja paduan rendah | |||||||||

| jinis | piring | Diameter kawat | longkangan ROOT | welding saiki | voltase welding | kacepetan welding | Jarak kontak tip-workpiece | Aliran gas | Sudut welding |

| T-shaped butt welding | 1.0 | 0.8 | 2.5~3 | 70~80 | 17–18 | 8~10 | 10 | 10~15 | 45° |

| 1.2 | 1.0 | 3~3.5 | 85~90 | 18~19 | 8~10 | 10 | 10~15 | 45° | |

| 1.6 | 1.0,1.2 | 3~3.5 | 100~110 | 18~19.5 | 8~10 | 10 | 10~15 | 45° | |

| 2.0 | 1.0,1.2 | 3~3.5 | 115~125 | 19.5~20 | 8~10 | 10 | 10~15 | 45° | |

| 2.3 | 1.0,1.2 | 3~3.5 | 130–140 | 19.5–21 | 8~10 | 10 | 10~15 | 45° | |

| 3.2 | 1.0,1.2 | 3.5~4 | 150-170 | 21–22 | 7.5~8 | 15 | 15~20 | 45° | |

| 4.5 | 1.0,1.2 | 4.5~5 | 180–220 | 21–23 | 6.5~7.5 | 15 | 15~20 | 45° | |

| 1.2 | 5~5.5 | 200-250 | 24–26 | 6.5~8 | 10~15 | 10~20 | 45° | ||

| 6 | 1.2 | 5~5.5 | 230–260 | 25–27 | 6.5~7.5 | 20 | 15~20 | 45° | |

| 6 | 220–250 | 25–27 | 5.5~7.5 | 13–18 | 10~20 | 45° | |||

| 4~4.5 | 270–300 | 28–31 | 10~11.5 | 13–18 | 10~20 | 45° | |||

| 8,9 | 1.2,1.6 | 6~7 | 270–380 | 29–35 | 6.5~7.5 | 25 | 20–25 | 50° | |

| 8 | 1.2 | 5~6 | 270–300 | 28–31 | 9~10 | 13–18 | 10~20 | 45° | |

| 1.2 | 7~8 | 260-300 | 26–32 | 4~5.5 | 15~20 | 10~20 | 50° | ||

| 1.6 | 6.5~7 | 300-330 | 30–34 | 5~5.5 | 15~20 | 10~20 | 50° | ||

| 12 | 1.2,1.6 | 7~8 | 270–380 | 27–35 | 4.5~6.5 | 20–25 | 20–25 | 50° | |

| 1.2 | 7~8 | 260-300 | 26–32 | 4~5.5 | 15~20 | 10~20 | 50° | ||

| 1.6 | 6.5~7 | 300-330 | 30–34 | 5~6 | 15~20 | 10~20 | 50° | ||

Cathetan:

1. MIG welding nggunakake gas inert, utamané digunakake kanggo welding saka aluminium lan wesi, tembaga lan wesi, titanium lan wesi, uga stainless steel lan panas-tahan baja.MAG welding lan welding gas CO2 shielded utamané dipigunakaké kanggo welding baja karbon lan alloy kurang baja kekuatan dhuwur.

2. Isi ing ndhuwur mung kanggo referensi, lan paling apik kanggo njupuk paramèter proses welding optimal liwat verifikasi eksperimen.Dhiameter kabel ing ndhuwur adhedhasar model nyata.